Table of Contents

FY25 Targets

Due to changes in business division strategy

Review of goals during the period

Re-set goals for FY25

Quantitative results against goals

Qualitative review of this fiscal year

Symbolic initiatives of this period

Responsible Manufacturing Practical Report Vol. 1

Responsible Production

Report vol.1

Table of Contents

HERALBONY's Declaration of Responsible Manufacturing is:

The announcement was made to coincide with the rebranding that will accompany the logo change in June 2024.

As HERALBONY continues to grow over the next 10 to 20 years,

We will not contribute to creating a negative environment in the manufacturing of our own products.

This declaration was born from that idea.

At HERALBONY, our products are:

It's not just a fashion item,

They are a force that delivers ideas and messages to society.

We do not want to impose a burden on manufacturers or the natural environment during the manufacturing process.

As much as possible, try not to make choices that could unknowingly step on someone else's toes.

That's how I feel.

This past year has been the starting point for us to take on the challenges of implementing the policies and goals set out in the Declaration on the ground.

In this report, we look back on the progress made over the past year.

Regarding our policy of "responsible manufacturing,"

How to take action

I'll let you know what I learned.

FY25 Targets

Providing quality products that will last a long time

Building relationships without excessive bias to produce the right amount

More than 60% of the products have had at least one factory tour during the production process

Aiming to ensure traceability of 80% of final manufacturing, 50% of processing, and 30% of raw materials

Materials with low environmental impact

Increase usage rate to 50% or more

Review of mid-term goals due to changes in business division strategies

As the brand expanded, the speed of product planning and development naturally increased. With a small number of staff and an unestablished production base and cycle, the time available for selecting materials and building a supply chain became shorter than ever. As the business grew, a gradual gap began to emerge between the "responsible manufacturing" goal set at the beginning of the fiscal year and reality.

Re-set goals for FY25

- 1. 20% of the main materials in all products meet our in-house selection criteria.

- 2. Of all product manufacturers, three were visited in the second half of FY25 (one visit every two months)

- 3. Of all product manufacturing processes, traceability is guaranteed for 50% of the final process, 30% of the processing, and 20% of the fabric.

Understanding the fabric is defined as knowing the factory that carried out the process of weaving the raw material into the material.

We created a framework for the team to periodically review the project, and also decided on a policy for selecting the main materials.

第1優先

第2優先

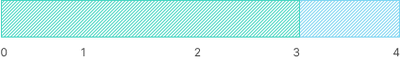

Quantitative results against goals

20% of the main materials in all products meet our in-house selection criteria.

16.18% / 100% (68 items in total)

At the same time, our relationships with manufacturers have deepened, and we are increasingly being introduced to fabrics that are scheduled to be certified in accordance with our company's plans, and we are increasingly being shared with information about fabric manufacturers.

In the future, we will create a system that will allow us to increase our options by ensuring sufficient lead time for planning and production and extending the time required for material selection and fabric production.

Additionally, we plan to develop a process to update our standard products to fabrics that meet our selection criteria.

Visit three manufacturers of all products in the second half of the year (visit once every two months)

Seeing the manufacturing site firsthand and learning about the people who make our products not only deepened my feelings about the products, but also gave me confidence when delivering them to customers.

Furthermore, building relationships of trust with factories also contributes to improving product quality.

From the beginning of the next fiscal year, we will establish a regular schedule of visits and, through continued re-visits, we hope to deepen our dialogue with the manufacturing site and foster close relationships.

Of all product manufacturing processes, we guarantee traceability for 50% of final manufacturing, 30% of processing, and 20% of fabric.

20.59% / 100% (68 items in total)

On the other hand, when it comes to the fabric that serves as the "base" for expressing art through prints, it is difficult to produce original fabrics from a cost and time perspective, and manufacturers often use stock fabrics, so it is not easy to understand the background behind them.

Going forward, we will continue to deepen our cooperative relationships with manufacturers and engage in careful communication to make background information more visible. Currently, the production lot size per item is small, making it difficult to manufacture original fabrics on an item-by-item basis. However, we plan to build relationships with fabric manufacturers and create a system and environment that can better guarantee the background of the materials we use.

63.24% / 100% (68 items in total)

94.12% / 100% (68 items in total)

With the brand's growth expected to increase five or even tenfold in the future, we plan to continue building final manufacturing locations that match both capacity and quality.

Qualitative review of this fiscal year

Setting conditions on the supply chain, such as understanding the manufacturing background, takes time, money, and energy. We are fully aware that when those costs are reflected in the product price, even if customers understand the reasons, there will be times when they feel the price is high. For a brand aiming for 10-fold or 100-fold growth in a short period of time, the impact of price on sales is not small. Even so, we will continue to explore the scope of what can be put into practice in our own products, which are supported by many people, and will take on the challenge of fulfilling our responsibility as manufacturers, so that we can proudly say that we have taken a step forward in society's awareness of human rights once we have grown.

Symbolic initiatives of this period